RO SEAWATER DESALINATION SYSTEMS FOR YACHTS AND SUPERYACHTS

Designed to reliably endure extreme marine conditions, far from factory-trained service centers, the ECHOTec PRO-Series provides small to medium-sized commercial vessels and larger yachts with a dependable source of high-quality potable water.

Simple self-installation, if required and minimal maintenance effort, and operators’ input are the key features of these field-proven watermakers.

Because only track records count, ECHOTec PRO-Series desalination systems are built without finicky electronics or touch screens.

Despite the multitude of standard and optional system features such as real-time salinity monitor, hour meter, low/high-pressure safety shut off, fresh water flush, and failsafe product diverter, all functions are controlled by rugged mechanical components and low voltage electrical circuitry – more reliable and field repairable wherever you go. For freshwater capacities of more than 7,000 GPD / 26,495 Liters, the installation of any number of redundant operative BHL desalination modules provides unlimited output. More economical than a single large system, multiple desalination modules provide backup, ease transport as well as installation, and reduce the electrical start-up load by more than 40%. In times of low water demand, only the modules needed are operated for the lowest maintenance effort and ultimate cost efficiency. Upgrades are easy, fast, and available in 1,800 GPD and 7,000 GPD increments.

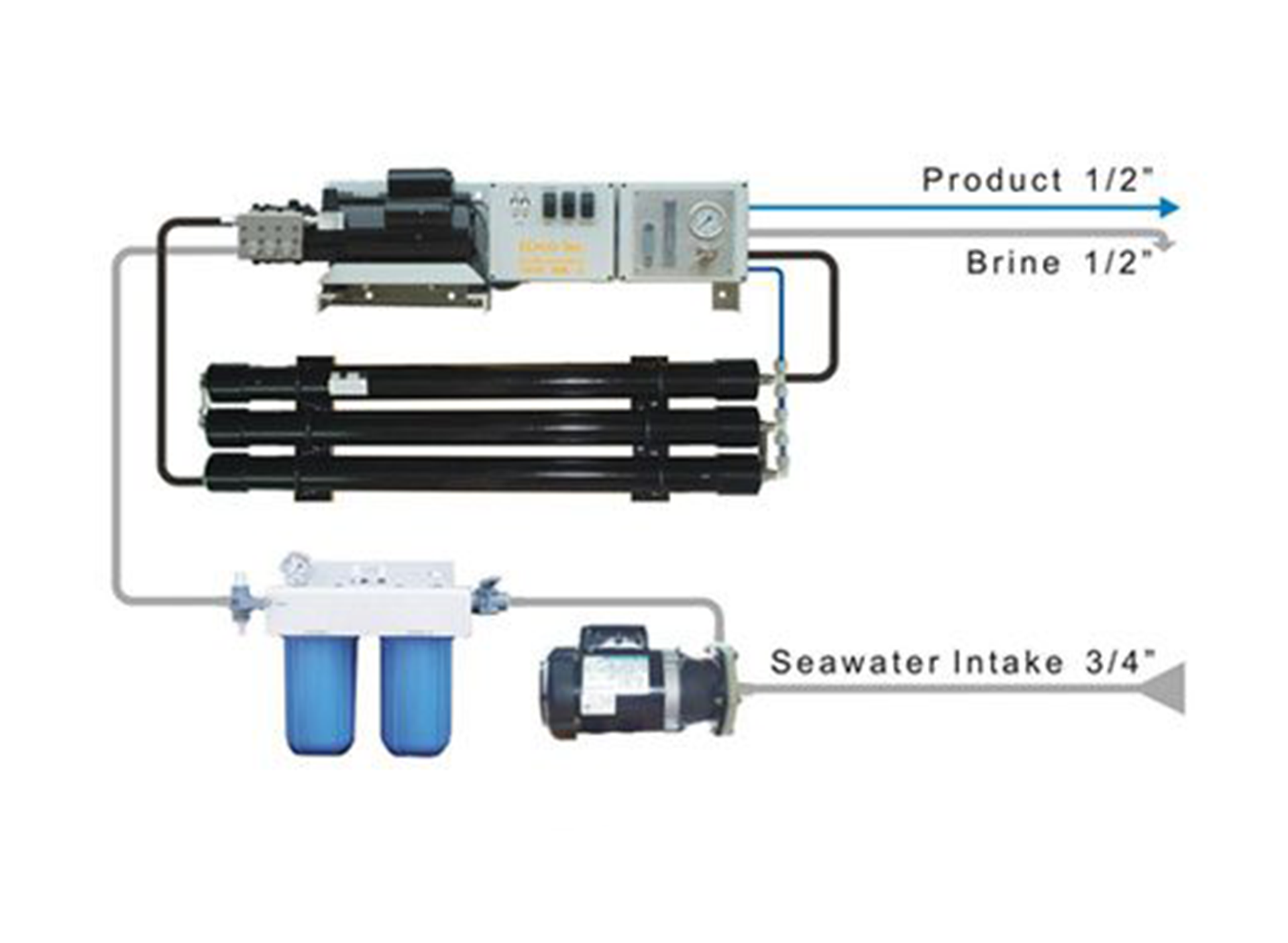

The newly engineered marine aluminum frame provides a tidy appearance while allowing easy access to the system components for maintenance. The semi-modular bulkhead mount systems or the self-contained vertical framed systems are space-saving and almost turnkey so that people without an engineering background can install them.

| Model | Production Gallons / Hour Per Day | Production Liters / Hour per Day | Pressure Vessels |

|---|---|---|---|

| 500-PRO-1 | 20 – 480 | 75 – 1,810 | 1 x 40 “ |

| 700-PRO-2 | 30 – 720 | 114 – 2,730 | 2 x 40 “ |

| 780-PRO-2 | 32 – 768 | 120 – 2,880 | 2 x 40 “ |

| 900-PRO-2 | 38 – 912 | 143 – 3,450 | 2 x 40 “ |

| 1200-PRO-3 | 50 – 1,200 | 190 – 4,540 | 3 x 40 “ |

| 1300-PRO-3 | 56 – 1,340 | 210 – 5,040 | 3 x 40 “ |

| 1800-PRO-4 | 75 – 1,800 | 280 – 6,810 | 4 x 40 “ |

| 3600-DUAL-8/S | 150 – 3,600 | 567 – 13,620 | 8 x 40 “ |

| 7000-PRO-4 | 292 – 7,000 | 1,105 – 26,495 | 4 x 40 “ |

| 14K-DUAL-8 | 584 – 14,000 | 2,210 – 52,990 | 8 x 40 “ |

Reverse Osmosis performance varies with the feed water temperature and salinity.

The rated performance is tested at 26ºC / 80ºF water temperature and salinity of 35000 ppm TDS.

*Also available in 36 VDC, 48 VDC, 90-96 VDC, and 180 VDC

**Prices shown do not include shipping, taxes, and/or customs duties (if applicable)

| Model | Production Gallons / Hour Per Day | Production Liters / Hour per Day | Pressure Vessels |

|---|---|---|---|

| 600-PRO-3 | 28 – 672 | 106 – 2,540 | 3 x 21 “ |

| 800-PRO-4 | 36 – 864 | 136 – 3,270 | 3 x 21 “ |

Reverse Osmosis performance varies with the feed water temperature and salinity.

The rated performance is tested at 26ºC / 80ºF water temperature and salinity of 35000 ppm TDS.

*Also available in 36 VDC, 48 VDC, 90-96 VDC, and 180 VDC

**Prices shown do not include shipping, taxes, and/or customs duties (if applicable)

Key Features:

- Self contained or semi-modular concept for space-saving, fast and easy self-installation

- All control systems are electro-mechanical – No electronic circuits close to seawater – Low voltage control circuit

- Spring-loaded automatic stainless steel pressure regulator – No leaking needle valves

- A Salinity meter, hour meter, and filter condition gauges are standard equipment

- High-pressure hoses with O-ring sealed stainless steel fittings – No corroding or cracking compression fittings

- RO pressure vessels with O-ring sealed stainless steel high-pressure fittings – No cracking NPT end plugs

- Three years warranty on all parts/components except consumables

- Lifetime warranty on Stainless steel high-pressure pump head and R.O. pressure vessel

- Triplex plunger pump for low revolution and pulsation-free raw water flow

- Separate control panel for remote operation

- Corrosion-resistant marine aluminum frame, epoxy primed and polyurethane top coated

- Widely available commercial-size sediment pre-filters (10”x 4.5”, Big Blue) are standard equipment

- Custom system configuration for tight installations at no extra charge

- Five years limited warranty on the stainless steel high-pressure pump

- Post-treatment pH buffer/hardener element saves up to 50% of produced water. Read more…

- No proprietary equipment – Consumables may be obtained anywhere (except pH buffer element)

- 7 days a week top-notch support and after-sales care!

Dimensions Pro Vertical 900-1800

Electrical Power Requirements

Bulkhead Mount System (500): 115/230V 60Hz single phase – 4,2/8.4 amps

230V 50Hz single phase – 5.4 amps

Bulkhead Mount System (700): 230V 50Hz single phase – 5.4 amps

Bulkhead Mount System (780): 230V 50Hz single phase – 5.4 amps

Bulkhead Mount System (all other models): 115/230V 60Hz single phase – 11.2 amps at 230V

230V 50Hz single phase – 9.2 amps at 230V

Vertical Mount System (3HP Motor): 115/230V 60Hz single phase – 11.2 amps at 230

230V 50Hz single phase – 11.2 amps at 230V

208-230/460V 60Hz three phase – 5.5 amps at 230V

230/380/440V 50Hz three phase – 3.8 amps at 38

Instruments:

The desalination system is equipped with all necessary instrumentation, for the control and supervision of the operation of the unit:

Pressure Gauges: Feed water, system entrance (316SS glycerin filled, Monel tube)

Feed water, high-pressure pump entrance (316SS glycerin filled, Monel tube)

RO pressure, (316SS glycerin filled, Monel tube)

Flow Meter: Product discharge

Conductivity: Digital product water quality monitor – ppm TDS

The following automatic emergency shut-off functions are provided: Low feed water pressure (e.g. seawater intake or pre-filters clogged) High RO pressure

Tank full (float switch optional)

| Bulk Mount System | Inches | Centimeters | Weights (kg/lb) |

|---|---|---|---|

| Pump / Control Unit | 42″ W x 11.5″ D x 11.0″ H | 107cm W x 29cm D x 28cm H | 28.2 / 62.0 |

| Pressure vessel – 500-PRO-1 | 49″ W x 4.0″ D x 3.5 ” H | 123cm W x 10cm D x 9cm H | 6.0 / 13.0 |

| Pressure vessel – 600-PRO-3 | 28″ W x 4.0″ D x 13″ H | 72cm W x 10cm D x 33cm H | 2.27 / 5.0 |

| Pressure vessel – 700-PRO-2 | 49″ W x 4.0″ D x 9.5 ” H | 123cm W x 10cm D x 24cm H | 12.0 / 26.0 |

| Pressure vessel – 800-PRO-4 | 28″ W x 4.0″ D x 15″ H | 72cm W x 10cm D x 48cm H | 9.1 / 20.0 |

| Pressure vessels – 900-PRO-2 | 49″ W x 4.0″ D x 9.5 ” H | 123cm W x 10cm D x 24cm H | 12.0 / 26.0 |

| Pressure vessels – 1200-PRO-3 | 49″ W x 4.0″ D x 13″ H | 123cm W x 10cm D x 33cm H | 18.0 / 39.0 |

| Pre-filtration System | 25″ W x 8.0″ D x 15″ H | 64cm W x 20cm D x 38cm H | 5.45/ 12.0 |

| Seawater Boost Pump | 14″ W x 8.0″ D x 8 ” H | 36cm W x 20cm D x 20cm H | 9.1 / 20.0 |

Standard Vertical Configuration

For installations where space is limited, the high-pressure pump, the flow/electrical control unit, the pressure vessels, and the pre-filters of the continuous duty, framed vertical mount system can be ordered in separate modules.

Where Do Superyachts Get Water?

Superyachts, with their luxurious amenities and extended voyages, require a reliable source of water to meet the needs of both crew and guests. After all, many of these superyachts have amenities and luxuries that need freshwater to operate.

The most popular way that these superyachts get clean water is by using an engine-driven watermaker or DC-powered watermaker. These systems convert seawater into high-quality drinking water, granting yachts unparalleled self-sufficiency during extended cruises or when venturing off the beaten path.

The reliability and efficiency of onboard watermakers have transformed the way these vessels operate. They reduce the dependence on external water sources and offer an uninterrupted supply of clean, fresh water. This ensures an opulent and seamless experience for crew and guests alike.

How Do Superyachts Get Water From the Ocean?

As mentioned above, superyachts get water through watermakers. But how do these watermakers work? The way that these watermakers work is by reverse osmosis. These systems work by forcing seawater through a specialized semi-permeable membrane that selectively filters out impurities, salts, and contaminants, leaving behind only the purest, drinkable water. The process is highly efficient and operates with minimal energy consumption, making it the preferred choice for superyachts aiming to reduce their environmental footprint.

This technology not only liberates superyachts from the need to rely on shore-based water sources but also exemplifies their commitment to sustainability and responsible resource management. As pioneers in oceanic exploration and luxury living, superyachts continue to set the bar high in embracing innovative solutions that enhance both comfort and environmental stewardship. If you are ready for such an enhancement, ECHOTec Watermakers is here to help you.

Are Freshwater Systems for Boats Durable?

Durability is of paramount importance when it comes to freshwater systems on boats. Having rugged construction using materials like aluminum can make a significant difference. Aluminum is renowned for its resilience in the harsh marine environment, as it resists corrosion and stands up to the rigors of life at sea. Freshwater systems crafted with this robust material offer longevity and reliability, reducing maintenance and repair needs.

Furthermore, these systems can be easy to install, often requiring fewer complex modifications to your boat. By opting for a rugged aluminum freshwater system, you not only ensure a steady supply of clean water but also enhance the overall efficiency and sustainability of your vessel. It’s a wise investment that makes life on board more comfortable and stress-free, even in the harshest of maritime conditions.

Yacht Water Filters vs. Watermakers

Yacht water filters and watermakers serve distinct purposes, with one emerging as the superior choice for ensuring a constant supply of clean water. Yacht water filters are undoubtedly crucial for removing sediment, contaminants, and impurities from the water you source. However, they fall short when it comes to providing a self-sufficient, long-term solution. Filters merely refine the quality of the water available at the time of use. Watermakers, on the other hand, are the pinnacle of marine water purification technology.

More About ECHOTec Watermakers

ECHOTec Watermakers is a premier manufacturer of watermakers. We offer a wide collection of watermakers, ranging from home desalination machines and desalinators for sailboats. Contact our professionals today to learn more about our products, including our 12V marine water makers.